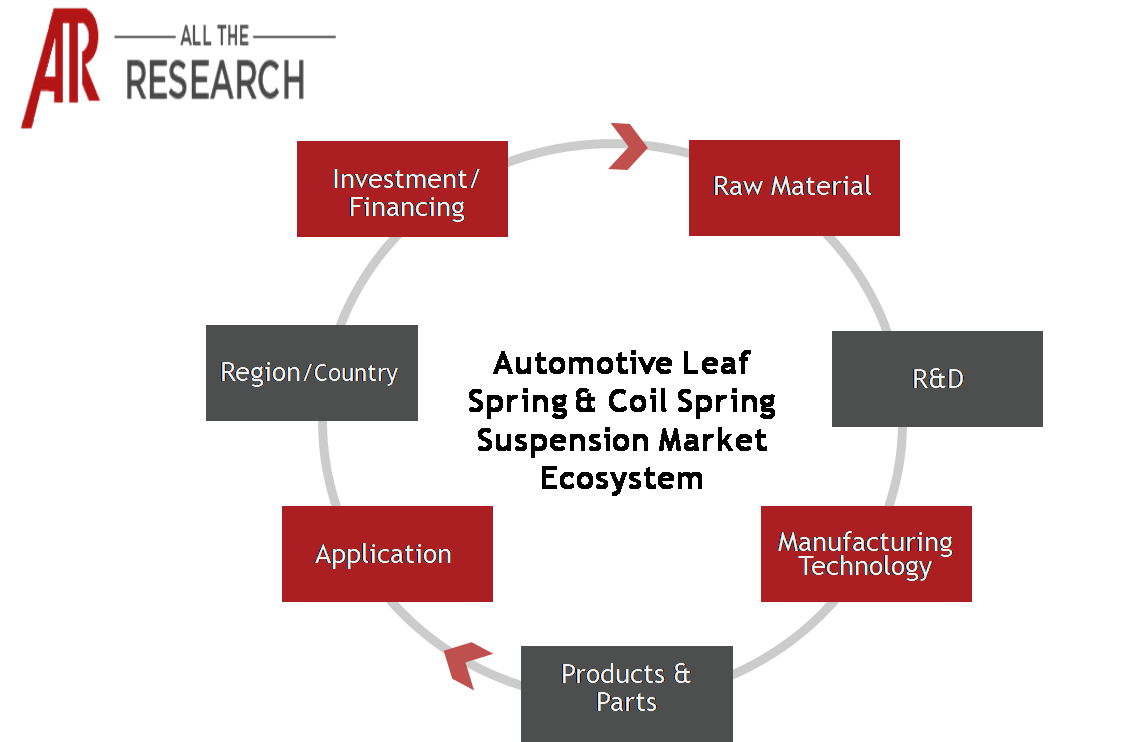

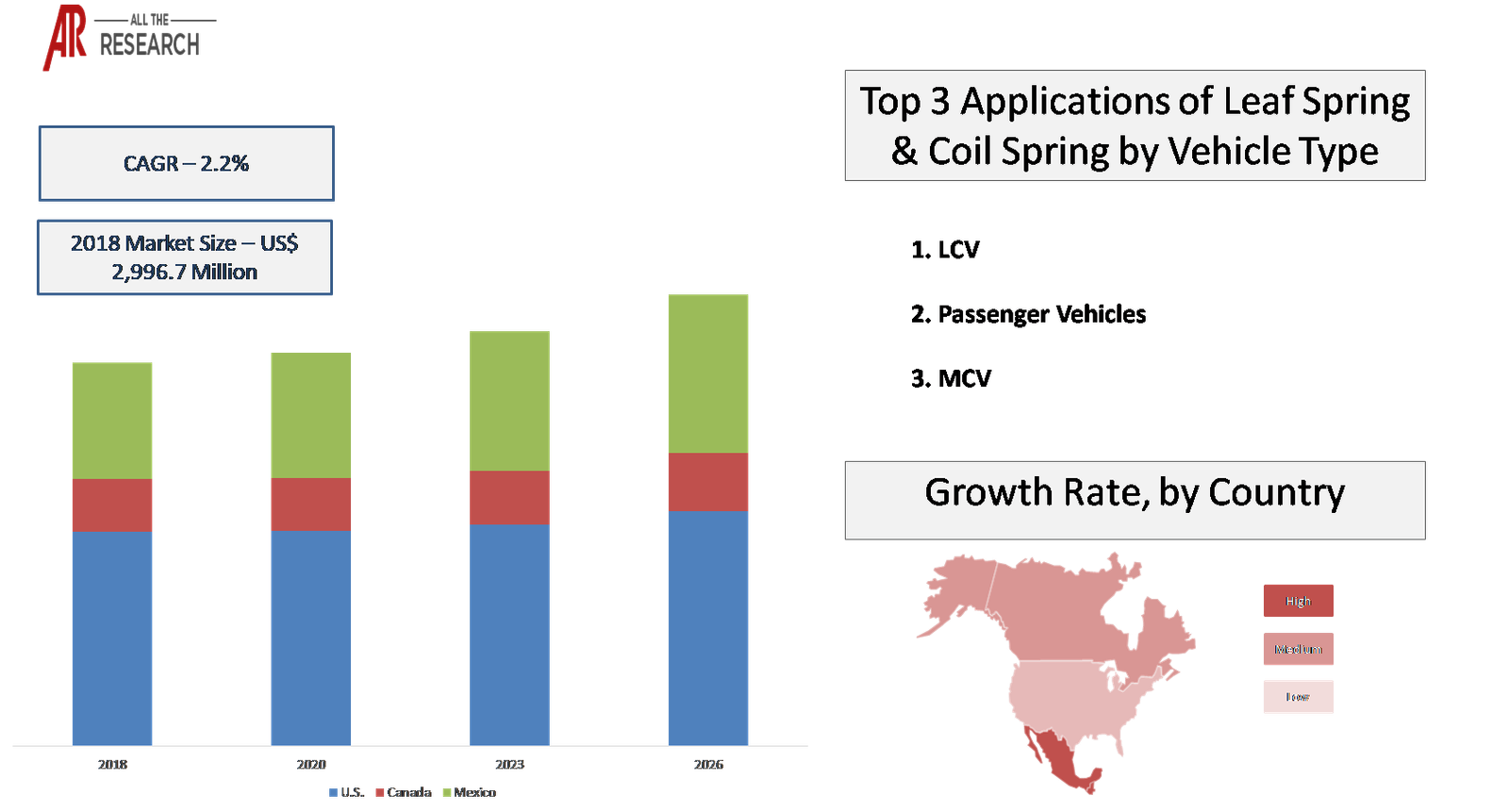

According to AllTheResearch’s analysis, the North America automotive leaf spring & coil spring suspension market ecosystem was valued at US$ 3,030.7 Mn in 2019 and is expected to grow at a CAGR of 2.2% during the forecast period. A leaf spring is a spring comprising of leaves and is commonly used for suspension in wheeled vehicles. It is a semi-elliptical arm consisting of one or more leaves, which are strips of steel or other materials that are meant to flex under pressure and yet maintain their original shape when not under pressure. Leaf springs are one of the oldest suspension components and are still being used in most LCVs and HCVs. There is another type of spring called coil spring, which has widespread usage in passenger cars.

North America is one of the dominating automotive manufacturing hubs across the globe. The automotive industry contributes a great deal to America’s economy and is responsible for 3% of America’s GDP. North American manufacturers are continuously spending huge sums for strengthening the manufacturing of automobiles and components in America. In 2018, North America sold more than 17.4 million cars and trucks. Nearly 11.3 million cars and trucks were produced at one of America’s 46 automotive assembly plants. Each vehicle these plants assemble contains 8,000 to 12,000 different components (and as many as 15,000 individual parts). More than 5,600 suppliers produce auto parts in the U.S. Together, they employ more than 871,000 U.S. workers. Automakers assemble approximately 85 million new cars and light trucks each year, worldwide. Building new plants and maintaining existing ones require hundreds of billions of dollars of investment each year.

The outbreak of COVID-19 has bought along with a global recession, which has impacted several industries. Along with this impact, COVID Pandemic has also generated a few new business opportunities for the North America Automotive Leaf Spring & Coil Spring Suspension market ecosystem. The overall competitive landscape and market dynamics of North America Automotive Leaf Spring & Coil Spring Suspension has been disrupted due to this pandemic. All these disruptions and impacts have been analyzed quantifiably in this report, which is backed by market trends, events, and revenue shift analysis. COVID impact analysis also covers strategic adjustments for Tier 1, 2, and 3 players of the North America Automotive Leaf Spring & Coil Spring Suspension Market.

Furthermore, the demand for composite material in automotive leaf spring & coil spring suspension ecosystem for reducing weight while increasing or maintaining the strength of the products is a major factor that is expected to drive the demand for automotive leaf spring & coil spring suspension ecosystem in this region. The weight of composite leaf spring was reduced up to 75%-85% compared to conventional steel springs. These trends and innovation in products and raw materials will further encourage the OEMs to go for composite material leaf springs that will accelerate the market demand for automotive leaf spring & coil spring suspension ecosystem during the forecast period. Though the usage of conventional leaf spring suspension units is witnessing a decline in passenger vehicle segment, the medium & heavy commercial vehicles segment is expected to remain the growth engine for the aftermarket during the forecast period, owing to a higher penetration of leaf springs in the segment.

Automobiles in the present scenario consist of approximately 63% iron and steel by weight. With increasing concern for the environment and rising adoption of electronics and other on-board vehicle systems, vehicle light-weighting continues to be a key concern for vehicle manufacturers. Weight reduction of vehicles can be achieved by the adoption of better and light materials. Suspension leaf spring is one of the possible ways for weight reduction in automobiles, as it accounts for 10% - 20% of the unstrung weight. The emergence of composite materials in the manufacturing of leaf springs has made it possible to reduce weight without any reduction on load carrying capacity and stiffness.

The adoption of composite materials for automotive leaf spring & coil spring suspension ecosystem helps in reducing the overall weight of conventional steel leaf springs by approximately 75%. This helps in improving fuel efficiency and in enhancing the riding quality of lightweight vehicles. Composite materials have more elastic strain energy storage capacity, excellent corrosion resistance, and high strength to weight ratio as compared to steel. Therefore, the key leaf spring manufacturers are adopting composite materials for the suspension system, which will create growth opportunities in the coming years.

However, the coronavirus outbreak is expected to have an impact on the global automotive industry. Automotive OEMs and component manufacturers have established task forces and war rooms to monitor and prevent the outbreak of coronavirus from impacting their manufacturing and supply chain. Automakers are struggling to find parts and prevent shortages in their supply chains, as the spread of coronavirus is rattling markets and threatening to negatively affect the manufacturing processes globally. According to United Auto Workers, when General Motors discovered a potential parts shortage, it airlifted supplies for its North American truck production. This has also impacted the automotive leaf spring & coil spring suspension market ecosystem players across supply chain.

|

Material Type |

Spring Type |

Vehicle Type |

Manufacturing Technology |

End User |

|

Metals |

Multi-Leaf Spring |

Passenger Vehicle |

HP-RTM |

OEM |

|

Composite Materials |

Parabolic Springs |

LCV |

Shot Peening |

Aftermarket |

|

|

Coil Springs |

MCV |

Prepreg layup |

|

|

|

HCV |

The parabolic leaf spring segment is the most attractive segment in the automotive leaf spring & coil spring suspension market ecosystem. These springs are widely being used across commercial vehicles, as they are lightweight and thus, help in reducing the overall weight of vehicles and thus, lower fuel consumption. Parabolic springs are also being used across mini loader trucks and buses, as they minimize vertical vibrations and impacts and bumps due to road irregularities while ensuring the safety of the loaded cargo.

Parabolic springs are more flexible, and they provide a comfortable ride to passengers. Parabolic leaf springs are lightweight and less expensive and have fatigue advantages. They can isolate more noise when compared to other leaf springs. Thus, these leaf springs are expected to witness growth over the coming years, as they can absorb more energy and offer good breaking torque. The increasing demand for buses, LCVs, and trucks, among others, in North America will foster the demand for parabolic leaf springs during the forecast period, that further boosts the demand of automotive leaf spring & coil spring suspension market ecosystem.

There are many trends that are having an impact on the automotive leaf spring & coil spring suspension market ecosystem forecast. These, when evaluated from a company’s perspective, can drive growth. Our numerous consulting projects have generated sizeable synergies across all regions and all sizes of companies.

| Company | Ecosystem Positioning | Total Revenue (2018) | Industry | Region |

| Rassini | Applications | US$ 978.0 Mn | Multi-Leaf Spring, Parabolic Taper Leaf, Vocational Parabolic, Coil Spring | Global |

| EMCO Industries | Applications | NA | Parabolic Spring | Americas, Europe |

| MW Industries, Inc. | Applications | NA | Coil Spring, Parabolic Spring, Others | Americas |

| NHK Spring Co., Ltd | Applications | US$ 6,170.1 Mn | Multi-Leaf Spring, Parabolic Spring, Coil Spring | Americas, Europe, Asia Pacific |

Very few markets have the interconnectivity with other markets like automotive components, automotive industry, and composite materials market, among others. Our Interconnectivity module focuses on the key nodes of heterogeneous markets in detail.

| Trends | Manufacturing Technology | Material Type | Spring Type |

| Shifting focus towards the use of composite material parts for vehicle weight reduction | HP-RTS | Composite Material | Parabolic |

Ask for free product review call with the author

Share your specific research requirements for a customized report

Request for due diligence and consumer centric studies

Request for study updates, segment specific and country level reports

North America Automotive Leaf Spring & Coil Spring Suspension Ecosystem Snapshot

North America Automotive Leaf Spring & Coil Spring Suspension Ecosystem Broad Heads

North America Automotive Leaf Spring & Coil Spring Suspension Ecosystem Trends

Trend Mapping

Overview

North America Automotive Leaf Spring & Coil Spring Suspension Ecosystem Sizing & Volume

Cross-segmentation

Competitive Intelligence

Company Profiles

North America Automotive Leaf Spring & Coil Spring Suspension Ecosystem Developments

North America Automotive Leaf Spring & Coil Spring Suspension Ecosystem Events & Rationale

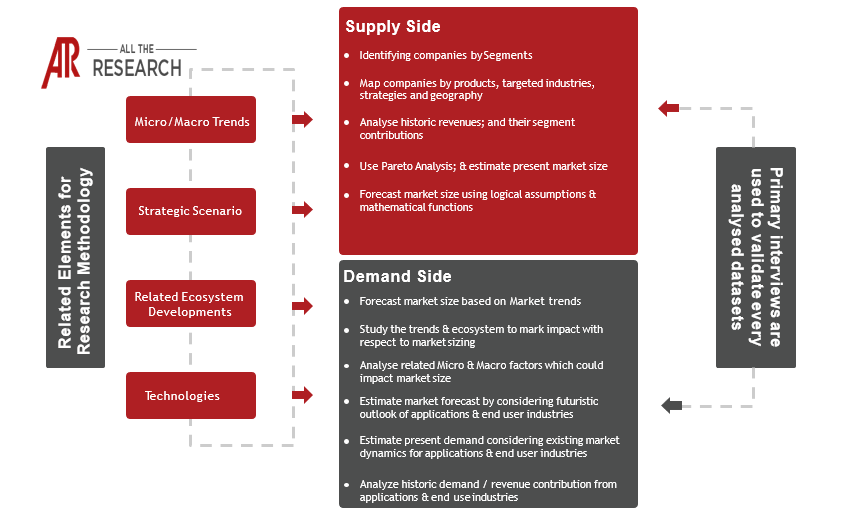

Research Methodology & Approach