A microfluidic chip is a set of micro-channels molded or etched on a material. These micro-channels are connected to the outside by inputs and outputs pierced through the chip, which enables the injection and removal of gases or liquids from the system. Microfluidic chips are cost effective, easy to manufacture, and easy to use. The unique chemical and physical properties that arise in fluids at micron size, coupled with the various advantages of microfluidics over conventional sized systems, are driving the growth of the microfluidic chips market ecosystem.

The increasing global patient pool in cancer, diabetes, and other immunodeficiency diseases, and the availability and affordability of diagnostics tests will drive the growth of the microfluidic chips market ecosystem. In the global microfluidic chips market ecosystem, government institutes and key market players are increasing their investments in R&D and new product development. Increasing technological advancements in fabrication and mass manufacturing of microfluidic chips will help reduce the manufacturing cost of the chips. Companies are focusing on streamlining the manufacturing process and filing patents for inventions, such as process patents, product patents, etc.

In recent years, a lot of start-up companies have entered the microfluidic chips market ecosystem. Big players can acquire or merge with them to produce synergies with respect to products and technologies and serve better and high-quality products to the end-users. There are a lot of microfluidic services companies looking for backward integrations and might go in for product innovations.

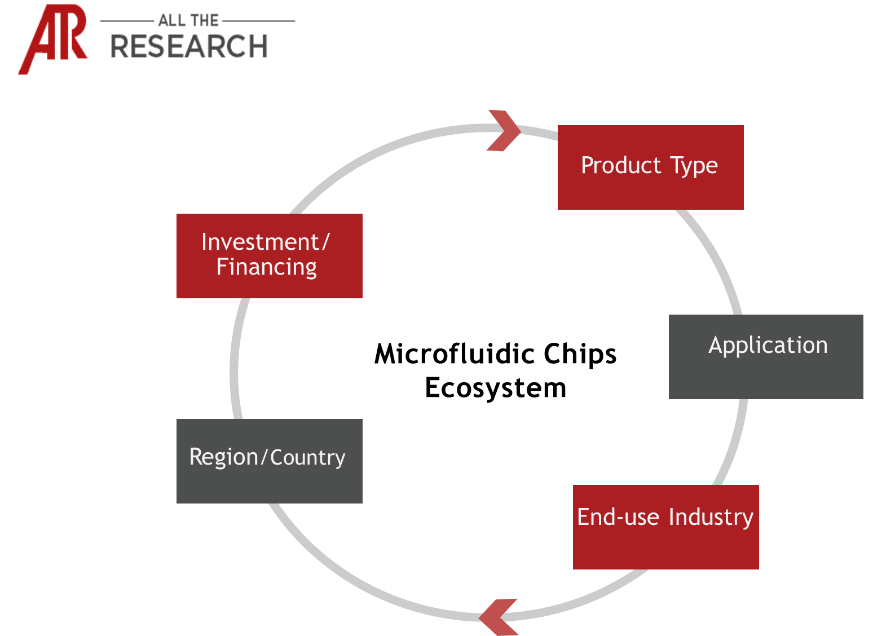

| Product Type | Application | End-use industry |

| Glass | Genomics | Healthcare |

| Silicon | Proteomics | Chemical |

| Polymer | In-vitro Diagnostics | Others |

| Others | Drug Delivery | |

| Micro-reactor | ||

| Capillary Electrophoresis | ||

| Others |

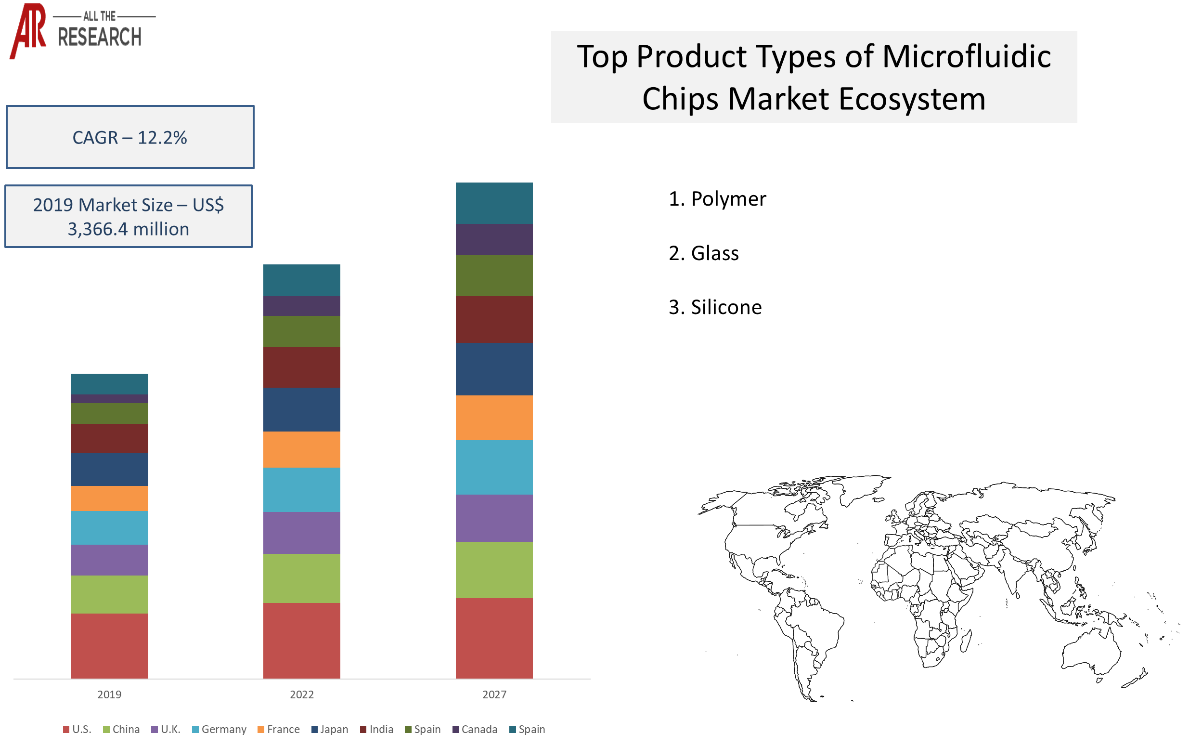

The main factors that need to be considered while choosing the material for fabrication of a microfluidic chip are the degree of integration, the application for which the chip is to be used, the properties of the material, and the fabrication process to be used. Based on type, the polymer microfluidic chips segment accounted for the highest share of 35.7% in the base year 2018 and is expected to grow at the highest CAGR of 12.7% over the forecast period. The polymer microfluidic chips are cost effective and can be used in various healthcare applications. The different types of polymer materials used for manufacturing microfluidic chips are Poly di-methyl siloxane (PDMS), thermoset polyester (TPE), polystyrene (PS), Polycarbonate (PC), Poly-methyl methacrylate (PMMA), Poly-Ethylene Glycol Diacrylate (PEGDA), Perfluorinated Compounds (PFEP/ PFA/PFPE), and polyurethane (PU).

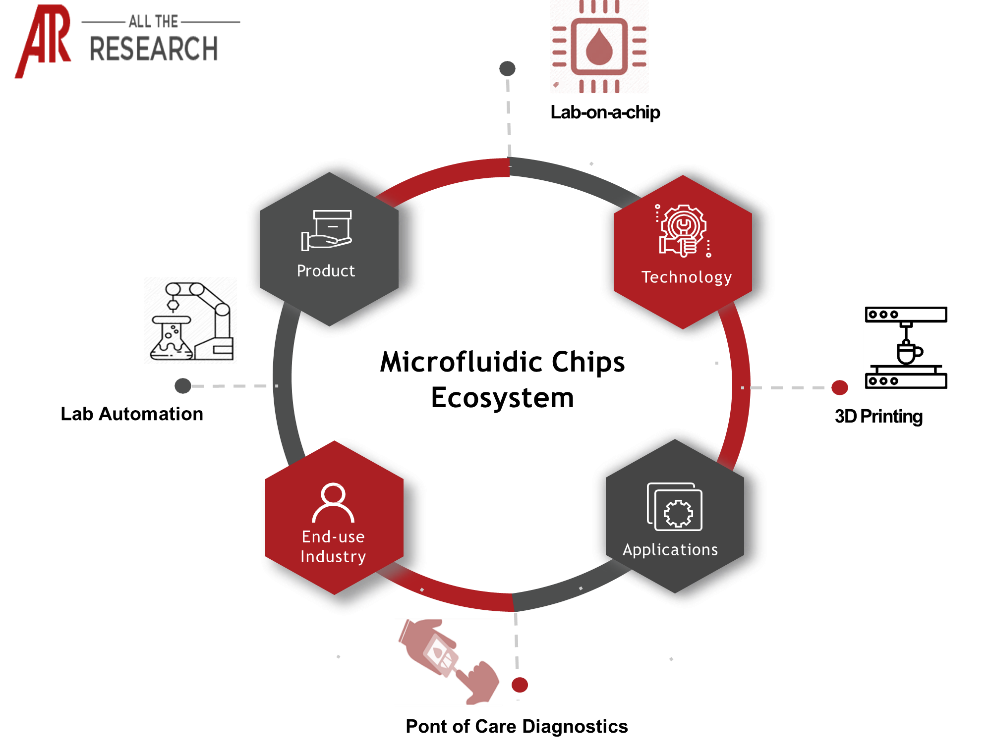

Microfluidic chips have maximum applications in the healthcare industry. Microfluidic chips can be used for point-of-care testing, drug delivery, drug discovery/screening, lab-on-chip, molecular diagnostics, bioreactors, and DNA/RNA screening (PCR), amongst others. Lab-on-chip can be used for the amplification of RNA/DNA and their detection. PCR testing is performed for the diagnosis of various diseases such as cancer, genetic diseases, and HIV, amongst others. Therefore, the commercialization of lab-on-chip will help reduce the cost of diagnosis of these diseases. Lab-on-chip also has potential applications in proteomics and cell biology.

The global microfluidic chips market was valued at US$ 3,366.4 Mn in 2019 and is expected to grow at a CAGR of 12.2% during the forecast period. The major factors driving the growth of the microfluidic chips market are rising preference for precision medicine, increasing demand for low volume sample analysis, growing penetration of microfluidics in in-vitro diagnostics.

North America accounted for a market share of 36.2% in 2019 and is expected to dominate the microfluidic chips market ecosystem throughout the forecast period. The growing demand for precision medicine, increasing research and development activities, and increasing funding for research in the US are some of the major factors in driving the growth of the microfluidic chips market in North America. China, Japan, and India are the major contributors to the growth of the microfluidic chips industry in the Asia-Pacific region.

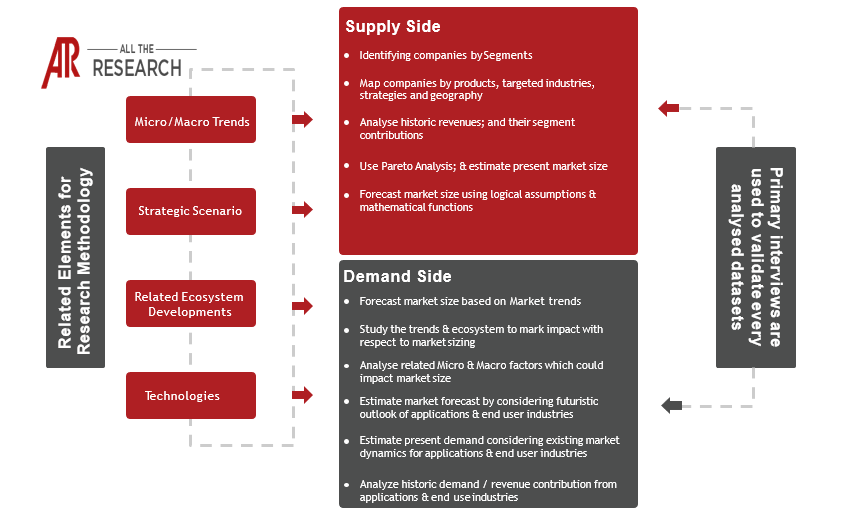

There are many trends that are having an impact on the market forecast. These, when evaluated from a company’s perspective, can drive growth. Our numerous consulting projects have generated sizeable synergies across all regions and all sizes of companies.

|

Company |

Ecosystem Positioning |

Total Revenue (2019) |

Industry |

Region |

|

Fluidigm Corporation |

Product provider |

US$ 117.2 mn |

Healthcare, Chemicals |

Global |

|

Agilent Technologies, Inc |

Product provider |

US$ 5,163 mn |

Healthcare, Chemicals |

Global |

|

Becton, Dickinson, and Company |

Product provider |

US$ 17.29 bn |

Healthcare, Chemicals |

Global |

|

Danaher Corporation |

Product provider |

US$ 17.9 bn |

Healthcare, Chemicals |

Global |

|

PerkinElmer Corporation* |

Product provider |

US$ 2.8 bn |

Healthcare, Chemicals |

Global |

*Revenue in for 2018

Very few markets have interconnectivity with other markets like Microfluidic Chips. Our Interconnectivity module focuses on the key nodes of heterogeneous markets in detail. 3D printing, Point-of-Care Diagnostics, Lab-on-a-chip, and Lab Automation markets are some of our key researched markets.

| Trends | Product Type | End-use industry | Impact |

| 3D printing is widely used in micro and nano scale microfluidic chip fabrications. Rapid prototyping is possible due to 3D printing and the mass production of devices is possible with the help of 3D printers. 3D printing particularly helps in cost reduction, miniaturization, and in manufacturing higher quality microfluidic chips. | Overall | 0.14% | |

| Based on technological advancements in 3D printing and material characteristics, the fabrication process needs specific types of materials, such as polymers, silicon, and glass. The biocompatibility of the material is an important aspect in manufacturing the chip. In addition to this, mechanical strength, optical transparency, low price, and electrophoresis compatibility are inspected before the usage. | Overall | xx% | |

| An increase in the use of microfluidic chip for precision medicine helps in decreasing the lead time for diagnosis and treatment. | Healthcare | xx% | |

| Companies are using microfluidic chips for the development of diagnostic tests for novel Corona virus | Overall | 0.15% |

Ask for free product review call with the author

Share your specific research requirements for a customized report

Request for due diligence and consumer centric studies

Request for study updates, segment specific and country level reports