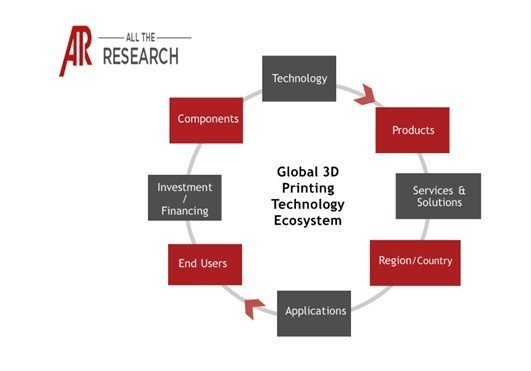

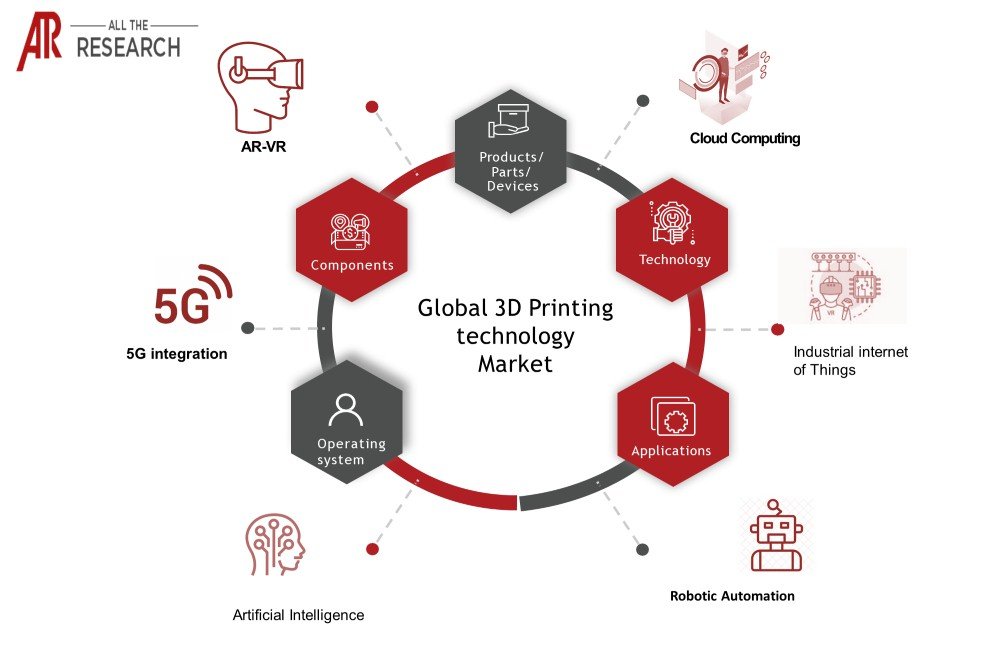

This report evaluates “Global 3D Printing Technology Market” by studying Ecosystem analysis, trend intelligence, and market revenue analysis With advancements in technology and innovation in products, 3D printing technology has found applications in multiple areas, such as jet engines, advanced prosthetics implants, and even living tissue printing. The market is constantly being driven by technological developments, which ensure higher flexibility and faster design. Manufacturers across different verticals have recognized the benefits offered by 3D printing such as faster production, easy accessibility, tangible design, and product testing, unlimited shapes and geometry, and better quality. With help of 3D printing technology, material wastage on each product is reduced by manufacturers.

Governments across the world have started investing in R&D of 3D printing technology, which will have a positive impact on technology adoption. The Dutch government invested ~USD 150 million in the 3D printing technology market for R&D. The 3D printing technology market, even after huge investments, has remained somewhat restricted due to the high equipment costs of installing 3D printers on an industrial scale.

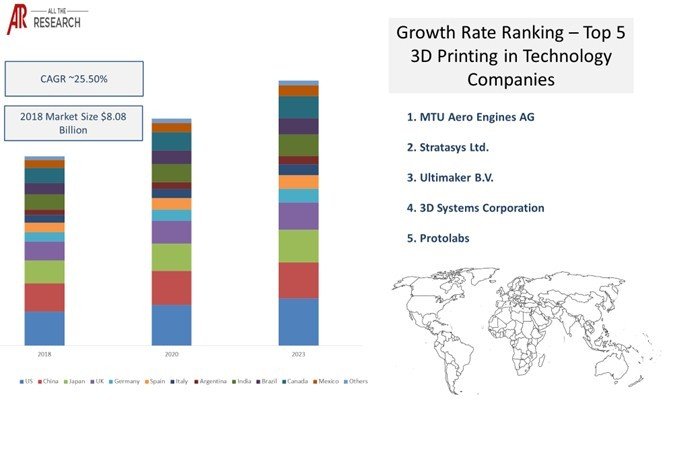

3D printing is a revolutionary and modern technology with the ability to bring transitional changes in manufacturing and businesses. It allows the conversion of digital documents into tangible objects and helps in designing, scanning, sharing, and transferring digital creations of actual objects into 3D printing. 3D printing technology has grown significantly, from the manufacturing of simple plastic models to producing useful components in the fields of fashion, surgical implants & prosthetics, batteries, robots, cloth, and others. According to AllTheResearch, the Global 3D Printing Technology Market will see substantial growth by USD 8.08 billion in 2018.

Some large companies like HP, Proto Labs, D Systems, etc., have entered the 3D-printing market, validating the space and boosting the overall market. These huge companies have brought in investment in research, trustworthiness, a large customer base, and marketing. The revenue for top 500 Fortune companies from 3D printing is irrelevant right now, as it is just 1% of their total revenue. But it will possibly stand for ~15-20% of the 3D printing market’s total revenue by 2023.

The segmentation of the Global 3D Printing Technology Market is based on technology. Technology is then further categorized into FDM, DMLS, Stereolithography, Inkjet printing, Electron beam melting, Laser metal deposition, Laminated object manufacturing, etc. Fused Deposition Modeling (FDM) has 19.52% share in this segment, which is the highest among all. FDM is a commonly used additive manufacturing technology for modeling, prototyping, and production. FDM is used for concept models and for building prototypes and functional parts. 3D printers, which use FDM technology for manufacturing components, create several layers by heating up thermoplastic materials into a semi-liquid form. Lack of skilled labor and cost of execution are hampering the global 3D printing technology Market.

The use of 3D printing in healthcare has been gaining remarkable momentum. This technology enables a patient-intensive customized approach by personalizing prosthetics and dentistry by printing human-sized bones, etc., with the help of bio-printing.

| Offering | Process | Application | Printer Technology | End-User |

| Material | Binder Jetting | Prototyping | Stereolithography | Automotive |

| Printer | Directed Energy Deposition | Tooling | Fused Deposition Modelling | Aerospace & Defense |

| Software & Solution | Material Extrusion | Functional Part Manufacturing | Selective Laser Sintering | Healthcare |

| Material Jetting | Direct Metal Laser Sintering | Consumer Electronics | ||

| Powder Bed Fusion | Polyjet Printing/Multijet Printing | Industrial | ||

| Sheet Lamination | Inkjet Printing | Power & Energy | ||

| Vat Photopolymerization | Electron Beam Melting | Others |

North America holds the highest market share in 3D printing technology, followed by Europe, Asia Pacific, and Latin America. North America has raised its investment for the development of innovative technologies and applications of 3D printing and this investment is in healthcare, electronics, defense & aerospace, and other applications. This will be driving the market in the future.

In Japan, 3D printing technology will reach a market size of US$32.7 Billion. As the world's second-largest economy and the new game-changer in global markets, China has the potential to grow at 16.3% over the forecast years. Numerous macroeconomic factors and internal market forces will shape the development and growth of the demand patterns in emerging countries in the Asia-Pacific region.

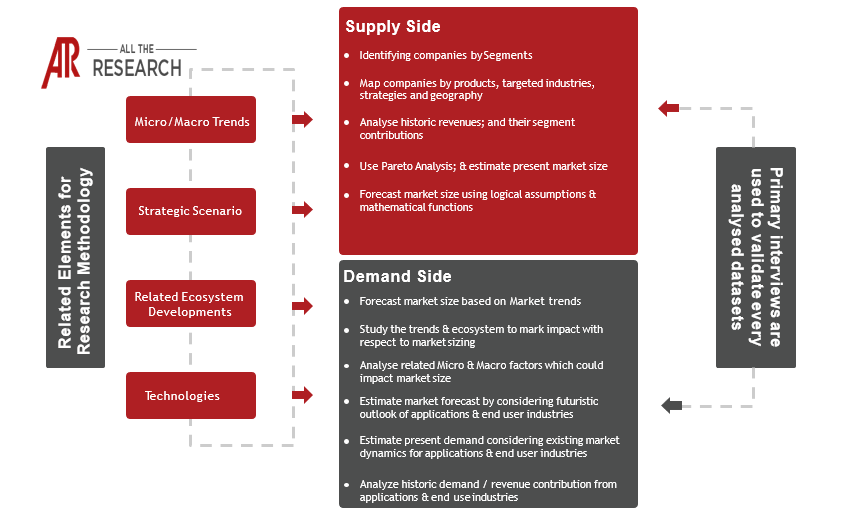

There are many trends that are having an impact on the market forecast. These, when evaluated from a company’s perspective, can drive growth. Our numerous consulting projects have generated sizeable synergies across all regions and all sizes of companies.

| Company | Ecosystem Positioning | Total Revenue | Market | Region |

| MTU Aero Engines AG | Product Provider | ~$530 million | Aerospace | Global |

| Stratasys Ltd. | Product Provider | ~$668.4 million | Digital printing | Global |

| Ultimaker B.V. | Product Provider | ~$70 million | 3D printing company | Global |

| 3D Systems Corporation | Product Provider | ~$646.84 million | 3D printing company | Global |

| Protolabs | Product Provider | ~$445.6 million | 3D printing company | Global |

Very few markets have interconnectivity with other markets like 3D printing. Our interconnectivity module focuses on the key nodes of heterogeneous markets in detail. Data Analytics, Cloud Logistics, Machine Learning, and Computer Vision markets are some of our key researched markets.

|

Trends |

Offering |

Market |

Application |

Impact |

|

3D printing is used for training technology engineering students by prototyping wind tunnel models. This enables students to practically understand the structure of an aircraft |

|

UAV |

Prototyping |

0.81% |

|

Aircraft manufacturers use 3D printing technology to make metal parts for the Technology Market. This helps original equipment manufacturers to lower the total cost of ownership and increase the quality of the parts |

Printer |

Aircraft |

|

0.64% |

|

Polyetherketoneketone (PEKK) material is used for 3Dprinting, as it is resistant to chemicals and can be used where the parts are exposed to chemicals and high temperatures. This material helps in reducing inventories and in making lightweight parts. |

Software & Solution |

|

Functional Part Manufacturing |

0.25% |

Ask for free product review call with the author

Share your specific research requirements for a customized report

Request for due diligence and consumer centric studies

Request for study updates, segment specific and country level reports