The development of advanced technologies like ARVR is revolutionizing the way the manufacturing industry works. There is a rising focus on digital transformation across the manufacturing sector. ARVR in manufacturing will be one of the key enablers for this digital transformation. Enhanced ARVR solutions will help make maintenance activities on the shop floor more efficient. Ford motors have adopted its own virtual reality technology. Virtual reality application in Ford motors captures human movements during equipment assembly, in order to ensure the safety and productivity of employees. The deployment of ARVR in manufacturing has reduced employee injuries by 70%. It also helps in increasing productivity.

Further, Hyundai Motors has been leveraging the ARVR technology right from the year 2015. Hyundai has advanced applications that allow users to point their smartphones and get relevant information about the maintenance of vehicles. In 2018, Hyundai Motors has announced its strategic investment on WayRay AG, a Swiss-based startup that offers holographic displays. Hyundai Motors believes that this collaboration will enable a brand-new ecosystem for smart mobility. Such new developments will boost the growth of the overall ARVR in the manufacturing market ecosystem. According to the analysis, the growth of global ARVR in the manufacturing market ecosystem is expected to grow at a CAGR of 43.4% in between 2018 to 2023.

In the aviation industry, ARVR in manufacturing provides step-by-step information for training the employees in assembling the aircraft wing section. The deployment of ARVR in this process has has reduced the assembling time by 35% in comparison to the traditional methods where the trainees rely on huge documentations. In 2017, Australia’s TAE Aerospace, along with Fountx, used AR smart glasses to make maintenance task more efficient. This virtual smart glass connects the technician with experts, which helps the experts in monitoring the maintenance process virtually, thereby assisting the technicians on floor. Lockheed Martin, Bell Helicopter, and TAE Aerospace are a few aerospace companies that have adopted ARVR in manufacturing applications. Newport News Shipbuilding that builds aircraft carriers for the U.S. Navy has deployed AR in manufacturing process to inspect ships. Traditionally, this was done by using 2D blueprints that consumes a lot of time. The implementation of AR for inspection has reduced the inspection time by more than 90%.

|

Raw Material |

Components |

Products, Parts and Devices |

Services and Solutions |

Application |

End-Use |

|

Silicon |

Sensors |

Head-Up Displays |

Documentation |

3D modeling |

Consumer Industry |

|

GaN |

Camera |

Head-Mounted Displays |

Visualization |

Training |

Healthcare |

|

Glass |

IMU |

Smart Glass |

3D Modelling |

Monitoring |

Automotive |

|

Plastic |

Processor |

Hand-Held Devices |

Navigation |

Others |

Aerospace |

|

SiC |

Modules |

Workflow Optimization |

Defense |

||

|

Metals |

Graphic Cards |

Others |

Logistics |

||

|

Others |

Audio ICs |

Retail |

|||

|

Memory |

Others |

||||

|

Display |

|||||

|

Others |

One of the biggest advantages of deploying ARVR in manufacturing is the efficiency in extracting accurate details from the digital overlay. This extra layer of digitization brings a sense of clarity to the employees working on a factory, thus improving workers’ productivity. Further, ARVR applications will make equipment maintenance in the manufacturing unit more efficient. Due to its immersive detailing, it is used in training of professionals, which helps reduce the operational cost involved in training the newly joined professionals.

BAE systems builds propulsion systems for hybrid buses using electric battery. The company uses Microsoft’s Hololens that reduces workers’ cycle time by 50% and training time up to 40%. Hence, most of the applications of ARVR in manufacturing ecosystem focus on bringing more efficiency and cost reduction in the long run. Currently, few companies that have deployed ARVR in manufacturing processes have witnessed the true potential of this technology. The deployment of ARVR in manufacturing is expected to rise in future.

There are many trends that are having an impact on the ARVR in manufacturing market forecast. These, when evaluated from a company’s perspective, can drive growth. Our numerous consulting projects have generated sizeable synergies across all regions and all sizes of companies.

|

Company |

Ecosystem Positioning |

Total Revenue (2018) |

Industry |

Region |

|

Apple Inc.

|

Solution & Service Provider |

$ 265.6 Billion |

Technology |

Global |

|

Google LLC. |

Solution & Service Provider |

$136.2 Billion |

Technology |

Global |

|

Qualcomm Inc.

|

Hardware Manufacturer |

$22.7 Billion |

Semiconductors |

Global |

|

Samsung Electronics Co. Ltd |

Solution & Service Provider |

$210.9 Billion |

Technology |

Global |

|

Microsoft Corporation |

Solution & Service Provider |

$110.3 Billion |

Technology |

Global |

Very few markets have interconnectivity with other markets. Our Interconnectivity module focuses on the key nodes of heterogeneous markets in detail. Automotive, Processor, and Head Mounted display are some of our key researched markets.

|

Trends |

Raw Material |

End-User |

Impact on Market |

|

Virtual reality and augmented reality tools are used by F500 companies to upskill their workforce. For instance, this may include training drivers by using virtual headsets for tackling hazardous situations. |

Logistics |

5.20% |

|

|

Hard plastic will dominate AR-VR product material space owing to the increasing penetration in industrial manufacturing and Aerospace & Defense sectors |

Plastic |

|

1.01% |

|

Head up displays are used by car manufacturers to make the driving experience convenient. They display the real-time data to the driver and hence, enable them to easily focus on passenger safety and convenience |

|

Automotive |

0.62% |

Ask for free product review call with the author

Share your specific research requirements for a customized report

Request for due diligence and consumer centric studies

Request for study updates, segment specific and country level reports

Introduction

Global ARVR in Manufacturing Ecosystem Definition

Scope of study

Ask for Customization

Sensitivity Analysis

Global ARVR in Manufacturing Ecosystem Snapshot

Global ARVR in Manufacturing Ecosystem Broad Heads

Global ARVR in Manufacturing Ecosystem Trends

Trend Mapping

Overview

Regulatory Mapping

Regulatory Impact

Global ARVR in Manufacturing Ecosystem Sizing & Volume

Cross-segmentation

Competitive Intelligence

Top Industry Players vs Trend Tagging

Company Profiling Summary

Company List & Fundamentals

Global ARVR in Manufacturing Ecosystem Events & Rationale

R&D, Technology and Innovation

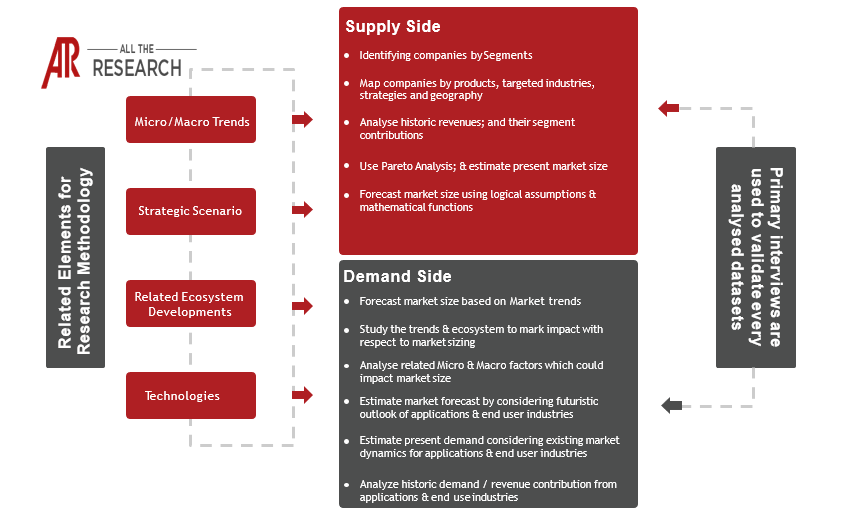

Research Methodology and Approach

Assumptions/ Inferences