The global plastic additives and master batches market was valued at USD 46.9 Billion in 2018 and is expected to reach USD 69.9 Billion in 2026, growing at a CAGR of 5.2% during the forecast period.

Plastic additives and master is an integrated compound of additives and pigments encapsulated in a heat process into a carrier resin which is cooled and cut into a granular shape. Plastic additives and master batches are used in various applications including in automotive, packaging, electronics, cables, and consumer goods for performance enhancers or processing aids.

Plastic Additives and Master Batches Market Segmentation |

|

| By Type | 1. Antimicrobial Additive Masterbatch |

| 2. Antioxidant Additive Masterbatch | |

| 3. Flame Retardant Additive Masterbatch | |

| 4. Others | |

| By Carrier Resin | 1. Polyethylene |

| 2. Polypropylene | |

| 3. Polystyrene | |

| 4. Others | |

| By End-use | 1. Packaging |

| 2. Automotive | |

| 3. Consumer Goods | |

| 4. Building & Construction | |

| 5. Agriculture | |

| 6. Others | |

| By Region | 1. North America (US and Canada) |

| 2. Europe (UK, Germany, France and Rest of Europe) | |

| 3. Asia Pacific (China, Japan, India and Rest of Asia Pacific) | |

| 4. Latin America (Brazil, Argentina and Rest of Latin America) | |

| 5. Middle East & Africa (GCC and Rest of Middle East & Africa) | |

The growth of the plastic additives and master batches market is primarily driven by the growing demand for recycled plastic, innovation in additive products, and growing demand for plastic additives over conventional materials. Moreover, rising demand from growing end-use industries, such as building & construction, automotive & transportation, and industrial sectors in emerging countries also drives the growth of the global plastic additives and master batches market. On the other hand, the availability of counterfeit and low costs products is creating a major hindrance to its market growth. However, continuous development in carrier resins for master batch and growing demand from several applications is expected to create major growth opportunities during the forecast period.

The antimicrobial additive masterbatch segment expected to grow at the fastest rate of 6.5% CAGR during the forecast period

Based on type, the global plastic additives and master batches market has been segmented into antimicrobial additive masterbatch, antioxidant additive masterbatch, flame retardant additive masterbatch, and another additive masterbatch. Due to its excellent properties like high durability and high mixture capability, an antimicrobial additive masterbatch is the most widely used plastic additives and master batches across the end-use industries, globally. Moreover, an antimicrobial additive masterbatch is largely used to make plastic products with rigid, flexible, ionic, nonionic, hydrophobic, or hydrophilic properties. These plastic products are transparent, provide excellent finish gloss, improved adhesion to non-porous surfaces, have resistance to breakage, and good flow and stability. Due to these aforementioned factors, antimicrobial additive masterbatch segment is expected to grow at the fastest rate throughout the forecast period.

Based on carrier resin, the polyethylene segment is expected to lead during the forecast period

Based on carrier resin, the plastic additives and master batches market has been segmented into polyethylene, polypropylene, polystyrene, and others. The polyethylene segment is accounted for the largest share of around 31% of the total market in 2018. Due to its excellent properties like moisture resistance, high toughness, and low density. Owing to its tensile strength, flexibility, ductility, stiffness, and resistance to water is an ideal solution for carrier resins in additive masterbatch applications. Again, polyethylene has a low tensile strength which is required in plastic bags & sheets, plastic wraps, toys, lids, buckets & containers, pipes, and others.

Based on application, the packaging segment is expected to lead during the forecast period

Based on the application, the plastic additives and master batches market has been segmented into packaging, automotive, consumer goods, building & construction, agriculture, and others. The packaging segment is expected to hold for around 28% of the total market, in 2018. This growth is attributed to the growing demand for packaging of personal care, household, building & construction, food & beverage, medical, and electrical & electronics applications. Furthermore, rapid industrialization, growing health awareness among consumers, changing consumer lifestyle, and development in packaging material & technology are major factors that drive the growth of plastic additive and master batches in packaging applications.

Asia-Pacific to dominate the plastic additives and master batches market throughout the forecast period

Asia-Pacific accounted for nearly 32% share of the global plastic additives and master batches market in 2018 and is expected to dominate the market throughout the forecast period followed by Europe and North America. Growing demand for masterbatch additives in end-user industries and strong economic growth in the Asia-Pacific region is one of the key factors driving the consumption of plastics additives and master batches in this region. Moreover, the growth of packaging, consumer goods, and the healthcare industry in key countries such as Japan, India, and China are also propelling the growth of plastic additives and master batches in the Asia-Pacific region. North America accounted for the highest CAGR in the global plastic additives and master batches market during the forecast period.

Company Profiles and Competitive Intelligence:

The major players operating in the global plastics additives and master batches market are Clariant AG (Switzerland), A. Schulman (US), Polyone Corporation (Japan), Tosaf Group (Israel), Penn Color, Inc. (US), Plastika Kritis S.A. (Greece), Plastiblends India Ltd (India), Ampacet Corporation (US), DOW Corning Corporation (US), and Polyplast Muller GmbH (Germany) among others.

Ask for free product review call with the author

Share your specific research requirements for a customized report

Request for due diligence and consumer centric studies

Request for study updates, segment specific and country level reports

Chapter 1 Executive Summary

1.1. Market Summary

1.1.1. Global Plastics Additives and Master Batches Market, 2016-2026, (USD Billion)

1.2. Market Snapshot: Global Plastics Additives and Master Batches Market

1.3. Market Dynamics

1.4. Global Plastics Additives and Master Batches Market, by Segment, 2018

1.4.1. Global Plastics Additives and Master Batches Market, by Type, 2018, (USD Billion)

1.4.2. Global Plastics Additives and Master Batches Market, by Carrier Resin, 2018, (USD Billion)

1.4.3. Global Plastics Additives and Master Batches Market, by End-use, 2018, (USD Billion)

1.4.4. Global Plastics Additives and Master Batches Market, by Region, 2018 (USD Billion)

1.5. Premium Insights

1.5.1. Plastics Additives and Master Batches Market In Developed Vs. Developing Economies, 2018 vs 2026

1.5.2. Global Plastics Additives and Master Batches Market: Regional Life Cycle Analysis

Chapter 2 Market Dynamics

2.1. Market Overview

2.2. Market Drivers

2.2.1. Growing demand for plastic additives over conventional materials

2.2.2. Innovation in additive products

2.2.3. Growing demand recycled plastic

2.3. Market Restraints

2.3.1. Availability of counterfeit and low costs products

2.4. Market Opportunities

2.4.1. Continuous development in carrier resins for master batch

2.4.2. Growing demand from several End-uses

2.5. Industry Value Chain Analysis

2.6. Pricing Analysis

2.7. Porter’s Five Forces Analysis

Chapter 3 Global Plastics Additives and Master Batches Market, by Type

3.1. Market Overview, by Type

3.1.1. Global Plastics Additives and Master Batches Market, by Type, 2016-2026 (USD Billion)

3.1.2. Incremental Opportunity, by Type, 2018

3.2. Antimicrobial Additive Masterbatch

3.2.1. Global Plastics Additives and Master Batches Market, by Antimicrobial Additive Masterbatch, 2016-2026, (USD Billion)

3.3. Antioxidant Additive Masterbatch

3.3.1. Global Plastics Additives and Master Batches Market, by Antioxidant Additive Masterbatch, 2016-2026, (USD Billion)

3.4. Flame Retardant Additive Masterbatch

3.4.1. Global Plastics Additives and Master Batches Market, by Flame Retardant Additive Masterbatch, 2016-2026, (USD Billion)

3.5. Others

3.5.1. Global Plastics Additives and Master Batches Market, by Others, 2016-2026, (USD Billion)

Chapter 4 Global Plastics Additives and Master Batches Market, by Carrier Resin

4.1. Market Overview, by Carrier Resin

4.1.1. Global Plastics Additives and Master Batches Market, by Carrier Resin, 2016-2026 (USD Billion)

4.1.2. Incremental Opportunity, by Carrier Resin, 2018

4.2. Polyethylene

4.2.1. Global Plastics Additives and Master Batches Market, by Polyethylene, 2016-2026, (USD Billion)

4.3. Polypropylene

4.3.1. Global Plastics Additives and Master Batches Market, by Polypropylene, 2016-2026, (USD Billion)

4.4. Polystyrene

4.4.1. Global Plastics Additives and Master Batches Market, by Polystyrene, 2016-2026, (USD Billion)

4.5. Others

4.5.1. Global Plastics Additives and Master Batches Market, by Others, 2016-2026, (USD Billion)

Chapter 5 Global Plastics Additives and Master Batches Market, by End-use

5.1. Market Overview, by End-use

5.1.1. Global Plastics Additives and Master Batches Market, by End-use, 2016-2026 (USD Billion)

5.1.2. Incremental Opportunity, by End-use, 2018

5.2. Packaging

5.2.1. Global Plastics Additives and Master Batches Market, by Packaging, 2016-2026, (USD Billion)

5.3. Automotive

5.3.1. Global Plastics Additives and Master Batches Market, by Automotive, 2016-2026, (USD Billion)

5.4. Consumer Goods

5.4.1. Global Plastics Additives and Master Batches Market, by Consumer Goods, 2016-2026, (USD Billion)

5.5. Building & Construction

5.5.1. Global Plastics Additives and Master Batches Market, by Building & Construction, 2016-2026, (USD Billion)

5.6. Agriculture

5.6.1. Global Plastics Additives and Master Batches Market, by Agriculture, 2016-2026, (USD Billion)

5.7. Others

5.7.1. Global Plastics Additives and Master Batches Market, by Others, 2016-2026, (USD Billion)

Chapter 6 Global Plastics Additives and Master Batches Market, by Region

6.1. Market Overview, by Region

6.1.1. Global Plastics Additives and Master Batches Market, by Region, 2016-2026, (USD Billion)

6.2. Attractive Investment Opportunity, by Region, 2018

6.3. North America Plastics Additives and Master Batches Market

6.3.1. North America Plastics Additives and Master Batches Market, by Type, 2016-2026 (USD Billion)

6.3.2. North America Plastics Additives and Master Batches Market, by Carrier Resin, 2016-2026 (USD Billion)

6.3.3. North America Plastics Additives and Master Batches Market, by End-use, 2016-2026 (USD Billion)

6.3.4. United States Plastics Additives and Master Batches Market, 2016-2026 (USD Billion)

6.3.5. Canada Plastics Additives and Master Batches Market, 2016-2026 (USD Billion)

6.4. Europe Plastics Additives and Master Batches Market

6.4.1. Europe Plastics Additives and Master Batches Market, by Type, 2016-2026 (USD Billion)

6.4.2. Europe Plastics Additives and Master Batches Market, by Carrier Resin, 2016-2026 (USD Billion)

6.4.3. Europe Plastics Additives and Master Batches Market, by End-use, 2016-2026 (USD Billion)

6.4.4. United Kingdom Plastics Additives and Master Batches Market, 2016-2026 (USD Billion)

6.4.5. Germany Plastics Additives and Master Batches Market, 2016-2026 (USD Billion)

6.4.6. France Plastics Additives and Master Batches Market, 2016-2026 (USD Billion)

6.4.7. Rest of Europe Plastics Additives and Master Batches Market, 2016-2026 (USD Billion)

6.5. Asia Pacific Plastics Additives and Master Batches Market

6.5.1. Asia Pacific Plastics Additives and Master Batches Market, by Type, 2016-2026 (USD Billion)

6.5.2. Asia Pacific Plastics Additives and Master Batches Market, by Carrier Resin, 2016-2026 (USD Billion)

6.5.3. Asia Pacific Plastics Additives and Master Batches Market, by End-use, 2016-2026 (USD Billion)

6.5.4. China Plastics Additives and Master Batches Market, 2016-2026 (USD Billion)

6.5.5. Japan Plastics Additives and Master Batches Market, 2016-2026 (USD Billion)

6.5.6. India Plastics Additives and Master Batches Market, 2016-2026 (USD Billion)

6.5.7. Rest of Asia Pacific Plastics Additives and Master Batches Market, 2016-2026 (USD Billion)

6.6. Latin America Plastics Additives and Master Batches Market

6.6.1. Latin America Plastics Additives and Master Batches Market, by Type, 2016-2026 (USD Billion)

6.6.2. Latin America Plastics Additives and Master Batches Market, by Carrier Resin, 2016-2026 (USD Billion)

6.6.3. Latin America Plastics Additives and Master Batches Market, by End-use, 2016-2026 (USD Billion)

6.6.4. Brazil Plastics Additives and Master Batches Market, 2016-2026 (USD Billion)

6.6.5. Mexico Plastics Additives and Master Batches Market, 2016-2026 (USD Billion)

6.6.6. Rest of Latin America Plastics Additives and Master Batches Market, 2016-2026 (USD Billion)

6.7. Middle East & Africa Plastics Additives and Master Batches Market

6.7.1. Middle East & Africa Plastics Additives and Master Batches Market, by Type, 2016-2026 (USD Billion)

6.7.2. Middle East & Africa Plastics Additives and Master Batches Market, by Carrier Resin, 2016-2026 (USD Billion)

6.7.3. Middle East & Africa Plastics Additives and Master Batches Market, by End-use, 2016-2026 (USD Billion)

6.7.4. GCC Plastics Additives and Master Batches Market, 2016-2026 (USD Billion)

6.7.5. Rest of Middle East & Africa Plastics Additives and Master Batches Market, 2016-2026 (USD Billion)

Chapter 7 Competitive Intelligence

7.1. Top 5 Players Comparison

7.2. Market Positioning of Key Players, 2018

7.3. Market Players Mapping

7.3.1. By Type

7.3.2. By Carrier Resin

7.3.3. By End-use

7.3.4. By Region

7.4. Strategies Adopted by Key Market Players

7.5. Recent Developments in the Market

7.5.1. Mergers & Acquisitions, Partnership, New Product Developments

Chapter 8 Company Profiles

8.1. Polyplast Muller GmbH

8.1.1. Polyplast Muller GmbH Overview

8.1.2. Polyplast Muller GmbH Products Portfolio

8.1.3. Polyplast Muller GmbH Financial Overview

8.1.4. Polyplast Muller GmbH News/Recent Developments

8.2. Clariant AG

8.2.1. Clariant AG Overview

8.2.2. Clariant AG Products Portfolio

8.2.3. Clariant AG Financial Overview

8.2.4. Clariant AG News/Recent Developments

8.3. A. Schulman

8.3.1. A. Schulman Overview

8.3.2. A. Schulman Products Portfolio

8.3.3. A. Schulman Financial Overview

8.3.4. A. Schulman News/Recent Developments

8.4. Polyone Corporation

8.4.1. Polyone Corporation Overview

8.4.2. Polyone Corporation Products Portfolio

8.4.3. Polyone Corporation Financial Overview

8.4.4. Polyone Corporation News/Recent Developments

8.5. Tosaf Group

8.5.1. Tosaf Group Overview

8.5.2. Tosaf Group Products Portfolio

8.5.3. Tosaf Group Financial Overview

8.5.4. Tosaf Group News/Recent Developments

8.6. Penn Color Inc.

8.6.1. Penn Color Inc. Overview

8.6.2. Penn Color Inc. Products Portfolio

8.6.3. Penn Color Inc. Financial Overview

8.6.4. Penn Color Inc. News/Recent Developments

8.7. Plastika Kritis S.A.

8.7.1. Plastika Kritis S.A. Overview

8.7.2. Plastika Kritis S.A. Products Portfolio

8.7.3. Plastika Kritis S.A. Financial Overview

8.7.4. Plastika Kritis S.A. News/Recent Developments

8.8. Plastiblends India Ltd

8.8.1. Plastiblends India Ltd Overview

8.8.2. Plastiblends India Ltd Products Portfolio

8.8.3. Plastiblends India Ltd Financial Overview

8.8.4. Plastiblends India Ltd News/Recent Developments

8.9. Ampacet Corporation

8.9.1. Ampacet Corporation Overview

8.9.2. Ampacet Corporation Products Portfolio

8.9.3. Ampacet Corporation Financial Overview

8.9.4. Ampacet Corporation News/Recent Developments

8.10. DOW Corning Corporation

8.10.1. DOW Corning Corporation Overview

8.10.2. DOW Corning Corporation Products Portfolio

8.10.3. DOW Corning Corporation Financial Overview

8.10.4. DOW Corning Corporation News/Recent Developments

Chapter 9 Preface

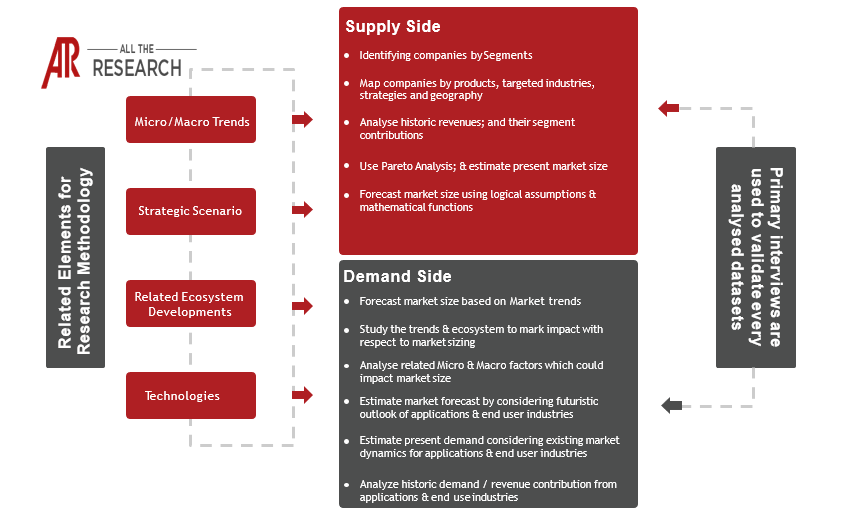

9.1. Data Triangulation

9.2. Research Methodology

9.2.1. Carrier Resin I – Secondary Research

9.2.2. Carrier Resin II – Primary Research

9.2.3. Carrier Resin III – Expert Panel Review

9.2.4. Approach Adopted

9.2.4.1. Top-Down Approach

9.2.4.2. Bottom-Up Approach

9.2.5. Supply- Demand side

9.2.6. Breakup of the Primary Profiles