The Global Anti-Corrosion Coating Market was valued at USD 13.8 billion in 2020 and is expected to reach USD 21.1 Billion by 2027, growing at a CAGR of 4.5% during the forecast period (2021–2027).

Anti-corrosion coating is a protective layer on a surface which acts as a barrier and prevents it from corrosion. According to the World Corrosion Organization, corrosion causes $2.5tr in damage to steel structures annually. Anti-corrosion coatings are majorly applied in construction, automotive, industrial, marine industries among others. These coatings protect the basic integrity of the materials against harsh environments. Increasing investment in infrastructure has been a leading factor driving demand for anti-corrosion coating market. In a report in the Times of India in 2017, India itself is estimated to construct around 30 airports. According to a report in Boeing, it was stated that 17 new airports and 17 runways are planned to be constructed in the Asia Pacific by 2030. This will drive the demand for anti-corrosion coating market. The Oil and Gas industry are also set to see a growth which in turn with be a factor boosting the growth of the anti-corrosion coating market. According to the Interstate Natural Gas Association of America, U.S and Canada will see a total USD 790 billion towards to investments of new oil and gas infrastructure from 2020 to 2035. Due to extensive use of anti-corrosion coatings in the oil & gas industry, there will be a rise in the anti-corrosion coating market. High growth in automotive market is also among foremost factors driving demand for anticorrosion coatings. International Trade Administration (ITA), in 2018, reported that 1.3 million new passenger cars and commercial vehicles were sold in the Australian market.

Several raw materials used to produce anti-corrosion coating cause damage to environment and human health. Due to this, governments have laid regulations that have restrained the growth of anti-corrosion coating market. The Marine Environment Protection Committee passed a resolution which recommend the governments to implement measures and actions to mitigate the use of anti-fouling paint. Thus, stringent policies have been adopted by the governments globally for the protection of the environment, have also created a setback for the anti-corrosion coating market. The fluctuation in raw materials is one of the major factors restraining the anti-corrosion coating market and thus affect the anti-corrosion coating market. According to the 2018 BP statistics, crude oil price increased to $72/ bbl from $55/bbl in 2017. Such fluctuations highly impact the cost of raw materials which include acrylic, epoxies, polyurethanes, among others which are used in the manufacturing of anti-corrosion coatings. This continuous fluctuation, will act as a restraint in the growth of the anti-corrosion coating market. The Covid 19 pandemic too had a negative impact on the automotive, aerospace, oil & gas industries. This is another factor which is expected to limit the growth of the anti-corrosion coating market growth.

Key players around the world are investing in research and development of environmentally friendly anti-corrosion coating products. For instance, Jotun launched Hardtop Flexi, in 2017, which is a flexible polyurethane and Hardtop XP which is a traditional high solid polyurethane. The Researchers at International Advanced Research Centre for Powder Metallurgy and New Materials (ARCI), Hyderabad, found, that halloysite and montmorillonite are environmentally friendly clay minerals with nanotubular and layered structures can be applied on Aluminum and Magnesium to improve corrosion resistance.

The epoxy segment is expected to be the largest segment in the global anti-corrosion coating market during the forecast period. Epoxy is the most widely used anti-corrosion coating owing to its increasing applicability across various end-use industries and owing to their excellent chemical resistance in varied environments. Moreover, the rising demand for epoxy coatings from the marine and oil & gas industries is also fueling the growth of the epoxy segment as it possesses protection when exposed to severe environments. During the forecast period, epoxy anti-corrosion coatings is projected to hold a market share of around 45% in terms of revenue.

The solvent-borne segment is expected to be the largest segment based on technology in the global anti-corrosion coating market during the forecast period. The growth of the solvent-borne technology segment is mainly attributed to the increasing demand for solvent-borne coatings from the automotive, infrastructure, and marine industries as they offer a major advantage as compared to water based coatings. Solvent borne coatings are comparatively less vulnerable to environmental conditions such as temperature. This will drive the demand for solvent borne coatings during the forecast period. Solvent-borne coatings are projected to record a 4.6% CAGR and reach USD 17.2 Billion by 2027.

Based on end-use industry, the marine segment is expected to be the fastest growing segment in the anti-corrosion coating of the global anti-corrosion coating market during the forecast period. Marine coatings prevent corrosion and aid in extending the of marine equipment. The constant need for restoration and maintenance is driving the growth of the anti-corrosion coating market. Moreover, developing countries such as India and China are witnessing a demand for new military as well as commercial ships which is expected to drive the demand for anti-corrosion coatings in the marine industry. The Indian navy targets 200 warships by 2027 as per the Economic Times news report of 2019.

Asia Pacific comprises of India and China which are the two fastest growing economies across the globe. China is the largest producer and consumer of anticorrosion coatings. Due to the rise in demand for anti-corrosion coating from the power generation, automotive and transportation sector in this region, there will be a growth in the anti-corrosion coating market. Heavy investments in construction projects will see a significant rise in the Asia pacific anti-corrosion coatings market. For instance, the Chinese government invested USD 2 billion on around 13 public housing projects in 2019. Additionally, the Asian Development Bank in 2020 approved a loan of USD 630 million for the development of the Vishakhapatnam-Chennai industrial corridor. All these factors will drive the growth of the anti-corrosion coating market in the Asia Pacific region.

Drivers

Restraints

Opportunities

There has been a major impact of Covid 19 on the economies worldwide. The Anti-Corrosion market has also felt the impact caused by the pandemic. The lockdown, followed by social distancing policies led to suspension of manufacturing operations. This cut of supply from the market. The demand in the market was impacted as consumers were hesitant to spend due to the uncertainty. This affected the demand pattern which had a major impact on the prices of raw materials. With minimal to almost nil labourers reporting to work at construction sites, there was a negative impact on the global anti-corrosion coating market.

| Sr. No. | Trends | Impact |

| 1 | Growth in automotive and aerospace industry | Positive |

| 2 | Governments significantly reduced protective coating material tenders due to economic crises | Negative |

| 3 | Fluctuating prices of raw material due to the oil crisis | Negative |

The key players operating in the Global Anti-Corrosion Coating Market are:

Ask for free product review call with the author

Share your specific research requirements for a customized report

Request for due diligence and consumer centric studies

Request for study updates, segment specific and country level reports

Section 1: Introduction

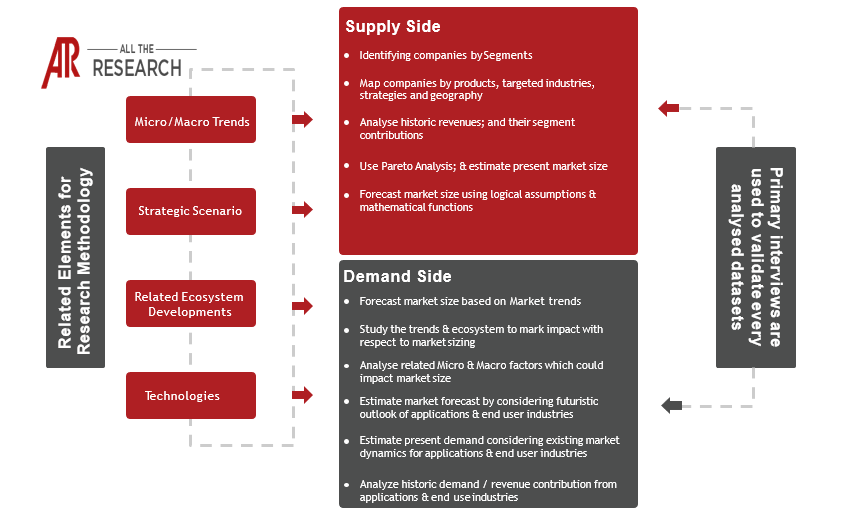

Section 2: Research Methodology

Section 3: Executive Summary

Section 4: Market Overview of Anti-Corrosion Coating Market

Section 5: Premium Insights

Section 6: Market Overview of Anti-Corrosion Coating Market

Section 7: Future Forecast & Impact of COVID-19

Section 8: Regional Market Analysis (US Millions)

Section 9: Competitive Scenario

Section 10: Company Profiles